- (801) 210-1303

- [email protected]

- Weekdays 9am - 5pm MST

DESCRIPTION

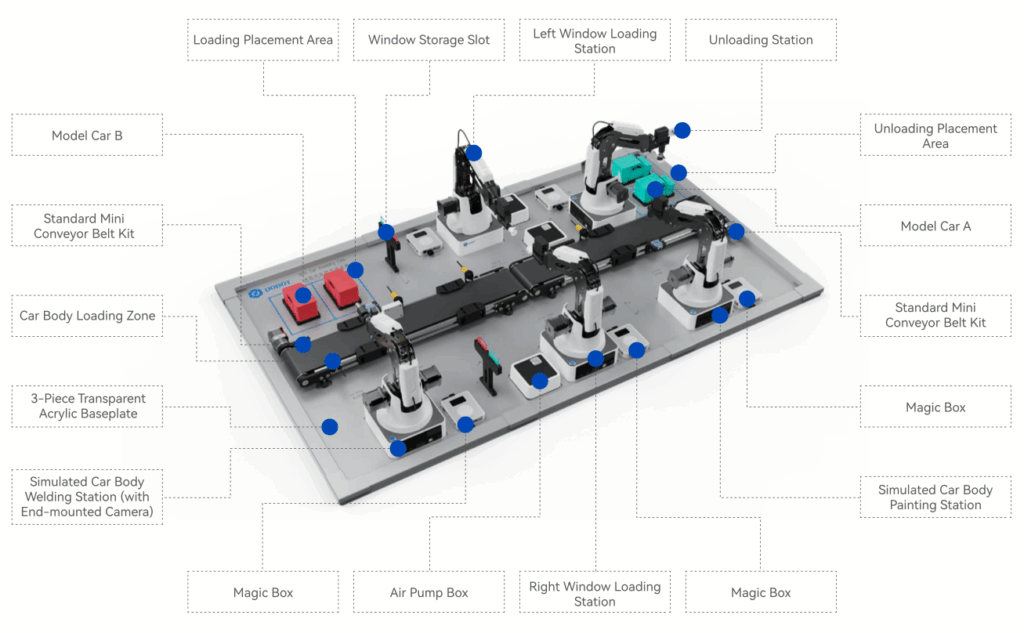

Simulates the entire automotive welding, painting, and assembly process, showcasing advanced automotive manufacturing techniques.

Al cameras intelligently recognize vehicle models and dynamically adjust welding paths and assembly plans, cultivating AloT system thinking.

Modular base and cable tray design make installation and transport easy while offering both aesthetic appeal and functionality.

Supports mixed-flow production for two different vehicle models, flexibly adapting to various production needs and promoting the concept of flexible manufacturing.

Lightweight robotic arm design perfectly demon- strates the automotive manufacturing process,

supporting full-process simulations of welding, spraying, and door assembly tasks.

Provides students with comprehensive practical experience in automotive

production processes and smart manufacturing, helping them under- stand the applications of robotics, Al, and automation.

Displays cutting-edge innovations ni smart manufacturing technology, allowing visitors to witness the charm of automated production firsthand.

By replicating the automotive production process, students gain in-depth understanding of the core concepts of smart manufacturing and automation technology.

Learn about modular systems and flexible production, exploring how ot adjust production models based on varying production demands.

Students learn robot operation, programming logic, and task scheduling by programming and controlling the desktop-level robotic arm.

Combining Al visual recognition with robot programming, students develop AloT system thinking and practical skills.

Funding goes to those who plan ahead, so add to your wishlist and submit your quote request.