AIT-400 Process

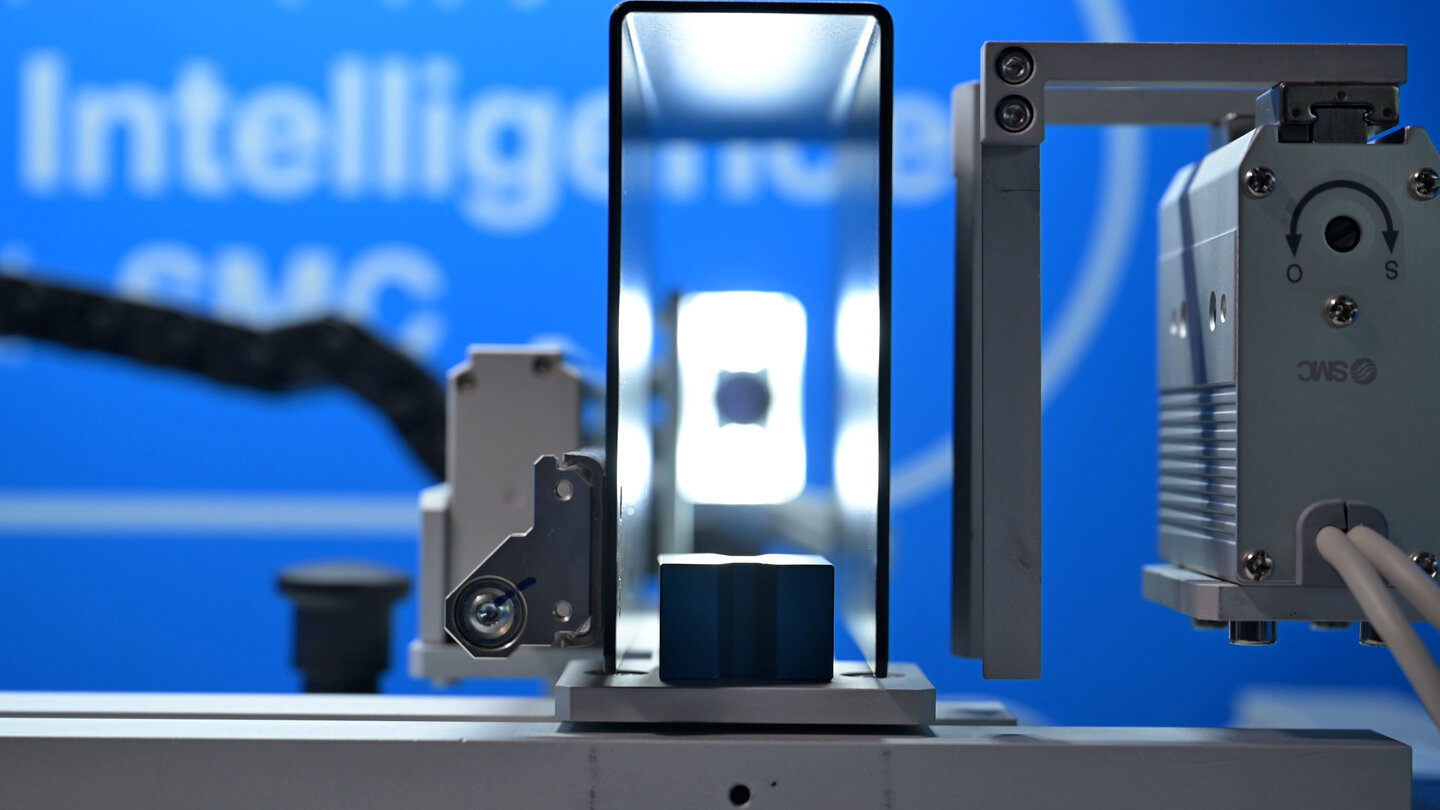

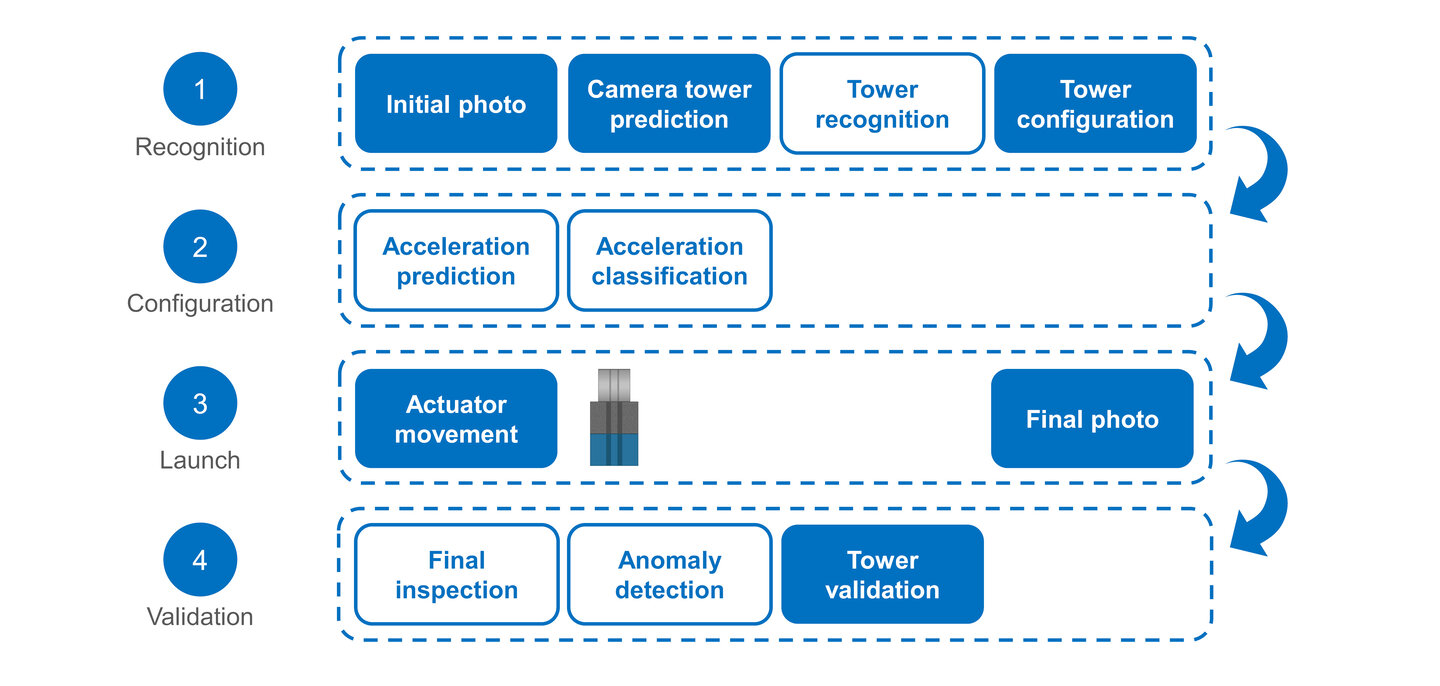

The problems to be solved with AI revolve around optimising the movement of an electric actuator: What is the maximum acceleration that can be applied to the load without falling and being damaged?

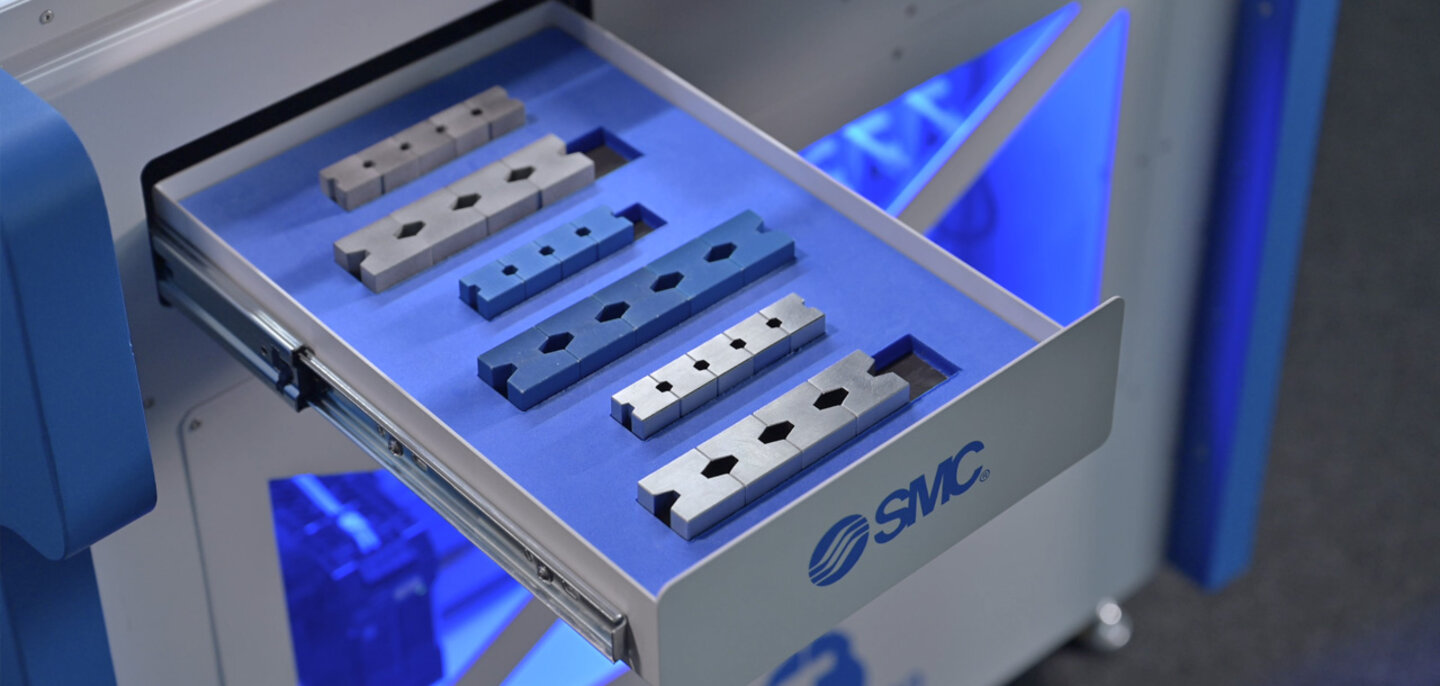

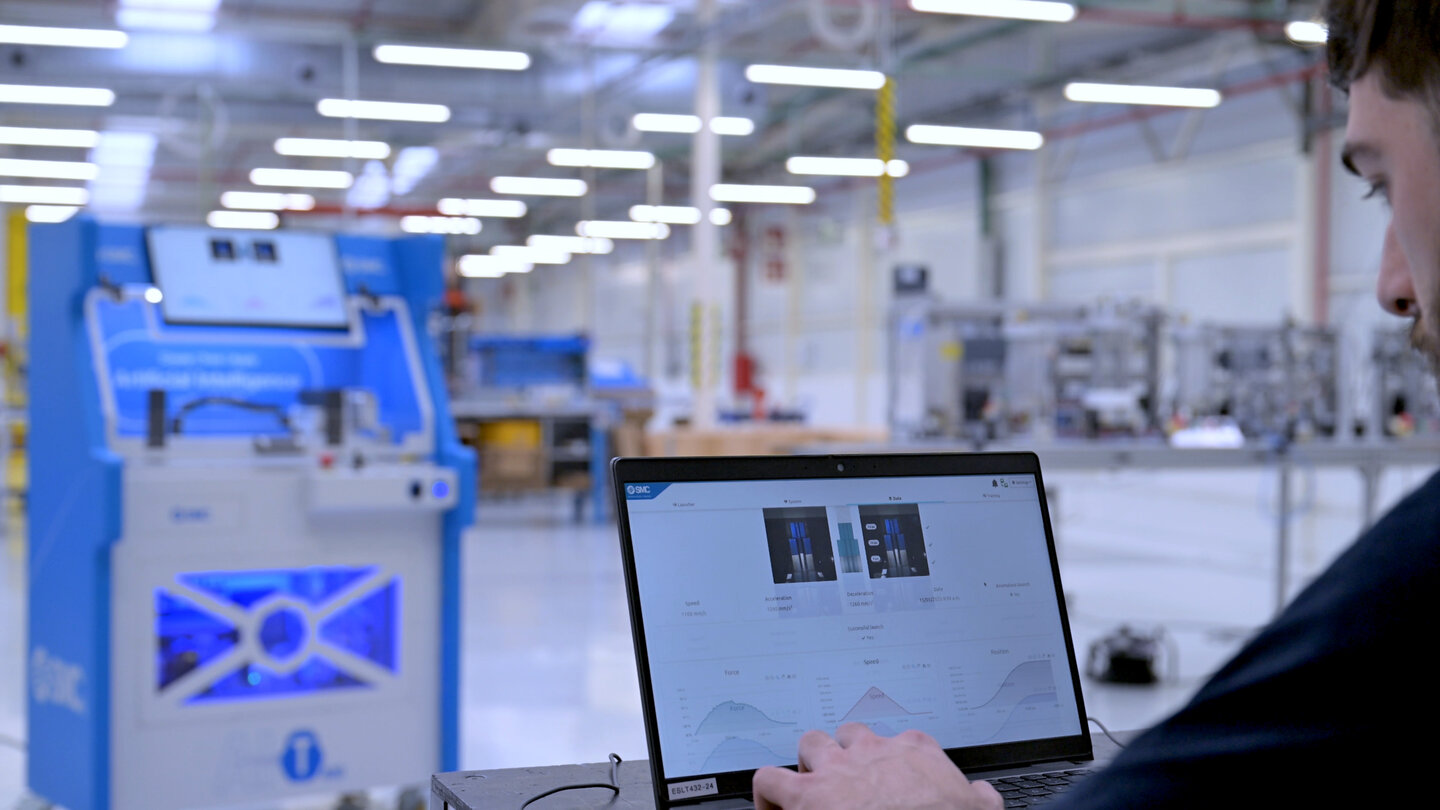

-To do this, the type of load must be recognised, so the AI will make a prediction based on a photo of the tower (1).

Then, there are two types of problems related to acceleration:

-Regression: Predicting the appropriate acceleration given a tower of pieces (2).

-Classification: Predicting whether or not the tower will fall, given a tower of pieces and an acceleration (3).

Finally:

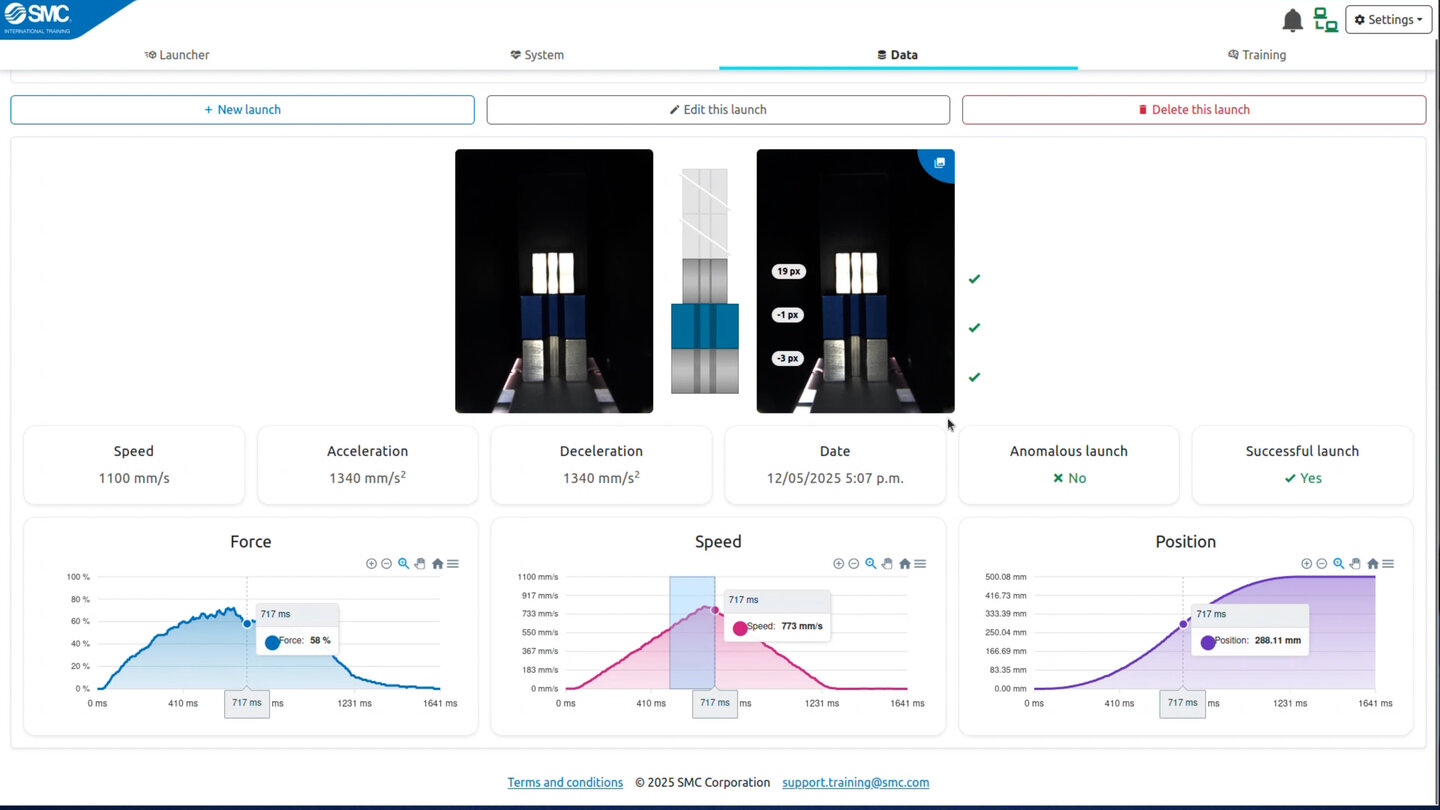

-After launching the actuator, another photo is taken at the final position, and it is evaluated whether the test was valid or not. In other words, it is evaluated whether the tower arrived in the correct position or not (4).

-The speed and force data from the electric shaft are analysed to detect anomalies in the movement of the actuator that may indicate a need for predictive maintenance (5).